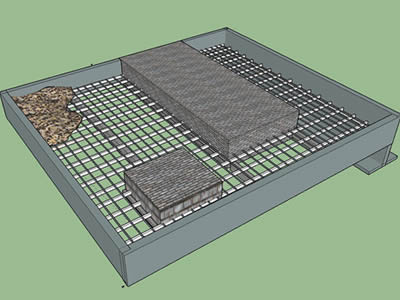

When you start a transformer project, you may need the transformer grating in advance. Then you raise the transformer on the grating and lay the cobblestone on the grating. The stones are very important for absorbing the oil leaked by the transformer. Additional, the stones are insulated to the electricity and can protect the safe of worker and inspectors. The grating under the cobblestone and above the transformer is also important. It can supply high load capacity to load the heavy transformer and it will supply excellent heat dissipation performance to maintain the normal working and safe of transformer. Here are two types of transformer grating, just refer to them and choose the perfect one.

Hot dipped galvanized steel bar grating

TG-01:

TG-01: Transformer grating has thick coating and bright surface for corrosion and rust resistance.

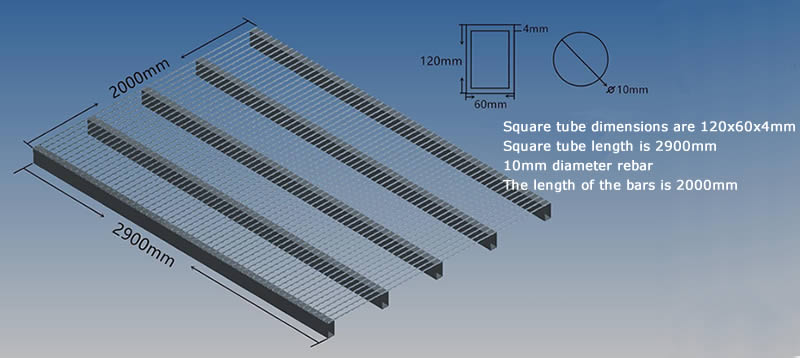

Hot dipped galvanized steel bar grating is composed of mild steel square pipe and rebar. The rebars are welded onto square pipe to form a rigid and solid structure. The steel bar grating panel will be hot dipped galvanized for rust and corrosion resistance. This type steel bar grating can supply high stability and loading capacity. Besides, the hot dipped galvanized coating can extend service life of grating and serve for the transformer bay for a long time.

Specifications

- Material: mild steel pipe and wire.

- Surface treatment: hot dipped galvanized after welded.

- Square tube dimension: 120 mm × 60 mm × 4 mm, 50 mm × 50 mm × 3 mm.

- Square tube length: 2900 mm.

- Rebar diameter: 10 mm.

- Rebar length: 2000 mm.

- Rebar spacing: no higher than 50 mm.

TG-02:

TG-02: Mild steel rebar.

TG-03:

TG-03: Mild steel square tube.

Specifications of hot dipped galvanized steel bar grating

Item

Width

length

TGG-01

2000

2900

TGG-02

1900

3000

TGG-03

1900

2800

TGG-04

1000

1950

TGG-05

1000

2050

TGG-06

870

2460

TGG-07

870

2540

TGG-08

950

2000

TGG-09

1000

2900

TGG-10

2000

2540

TGG-11

2000

2360

TGG-12

2000

2880

TGG-13

1900

2970

TGG-14

1000

1950

TGG-15

1000

2070

TGG-16

870

2580

TGG-17

870

2480

TGG-18

950

2000

TGG-19

2000

2500

TGG-20

1000

2880

TG-04:

TG-04: Steel bar grating drawing.

TG-05:

TG-05: Hot dipped galvanized steel bar grating is widely used in transformer bay.

Features

- Lightweight. Compared with other steel bar grating, it has lighter structure.

- Simple structure for easy installation.

- Hot dipped galvanized for corrosion and rust resistance.

- Narrow spacing to keep stones on the surface.

- Good heat dissipation. It is benefit for the heat dissipation for transformer and maintain safe.

Pultruded fiberglass grating

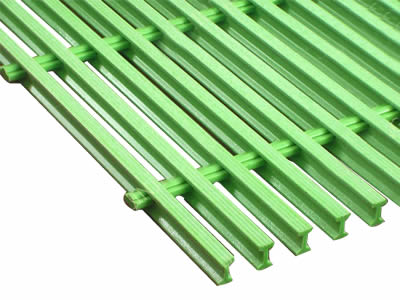

Pultruded FRP grating, also called pultruded fiberglass grating. It is made of various colors fiberglass I bars and round cross bar. The cross bars are pultruded into bearing bars to form a corrosive resistant and lightweight structure. Compared with molded fiberglass grating, the pultruded fiberglass grating has a higher load capacity than Molded Fiberglass Grating but the weight is lighter than that. Pultruded FRP grating comes in a variety of resins and colors and are available with or without a slip resistant gritted surface.

Specifications of pultruded FRP grating

- Material: fiberglass cross bar and bearing bar.

- Surface treatment: resin coated.

- Colors: yellow, green, blue, red and any other colors you want.

- Bearing bar height: 25 mm, 38 mm, 40 mm, 50 mm, 58 mm, 65 mm and others can be customized.

TG-06:

TG-06: Yellow pultruded fiberglass grating.

TG-07:

TG-07: Black pultruded fiberglass grating.

TG-08:

TG-08: Green pultruded fiberglass grating.

TG-09:

TG-09: Gray pultruded fiberglass grating.

Specifications of pultruded fiberglass grating

Item

Cross bar thickness

(mm)

Cross bar height

(inch)

cross bar top head width

(mm)

cross bar bottom head width

(mm)

Cross bar spacing

(mm)

Theoretical weight

(kg/m2)

TGP-01

25

1

30

30

13

13

TGP-02

25

1

30

30

30

10

TGP-03

25

1

15

15

10

17

TGP-04

25

1

15

15

23

11

TGP-05

38

1.5

15

15

10

19

TGP-06

38

1.5

15

15

15

16

TGP-07

38

1.5

15

15

23

13

TGP-08

38

1.5

15

15

35

10

TGP-09

40

1.6

40

40

27

19

TGP-10

40

1.6

40

40

40

17

TGP-11

40

1.6

40

40

60

14

TGP-12

40

1.6

30

30

20

14

TGP-13

40

1.6

30

30

30

12

TGP-14

40

1.6

30

30

45

10

TGP-15

58

2.2

15

15

10

32

TGP-16

58

2.2

15

15

15

27

TGP-17

58

2.2

15

15

23

22

TGP-18

65

5.5

30

30

20

17

TGP-19

65

2.5

30

30

30

15

TG-10:

TG-10: Pultruded fiberglass grating can be used for load stones and transformers.

Features

- High loading capacity.

- Corrosion and rust resistance.

- Narrow space prevents stones falling off.

- Various colors to blend with surrounding environments.

- Excellent heat dissipation performance.

- http://www.steelbargrating.org/frpgrating/transformer-grating.html